Blossom PV: Sustainability and upcycling at Imbotex Srl The - Accessories - Blossom Première Vision

In the lead up to Blossom Première Vision – the can’t-miss event dedicated to the Spring-Summer 2023 pre-collections – the Première Vision team shines a special light on the expert know-hows and excellence of its specially selected exhibitors.

Today we’re talking to Imbotex Srl, a company that puts sustainability at the heart of its business model.

Since 1955, Imbotex has specialized in the manufacturing of natural and technological textile padding for the fashion and furniture sectors. Engaged in a constant search for innovation, the Padua-based Italian company has in recent years focused on the production of 100% Italian-made textiles and eco-responsible materials.

With its Imbotex Lab, launched in 2019, the company’s goal has been to generate less waste and use less and less water through a production cycle based on a circular economy and upcycling model. Their production processes allow them to recycle fabric scraps, consume less energy, and reduce CO2 emissions.

A talk with Stefania Carniello, CEO of Imbotex SRL

Première Vision: Can you tell us how you combine natural materials with technological innovations in your padding collections?

Stefania Carniello: Flexibility and innovation are the hallmarks of our products, making them the ideal items in a variety of sectors, ranging from furniture to high fashion and professional sports. The search for latest generation high-tech fibers and innovative blends with natural fibers has given rise to exclusive paddings: these blends are created using patented production processes that offer leading-edge characteristics in terms of wearability, lightness and comfort.

The collection offers an excellent alternative to down and is washable, thanks to an exclusive chlorine-free process, which is kind to animals and the environment. The whole production in Imbotex plants is completely mechanical, zero waste, no use of water, and ecofriendly as we have eliminated all the chemicals products such as resins, powders, etc. For thermo-bonding we are using a PLA low-melting fiber, which is derived from wastes of cereals.

« Pursuing a fully sustainable lifestyle is not always easy, and more eco-friendly clothing options are becoming more necessary than ever. »

– Stefania Carniello, CEO of Imbotex Srl.

PV: You’re showing for the first time at Blossom. Why did you choose this event to present your collections?

SC: After attending Première Vision in Paris, we applied to exhibit our products at Blossom. Blossom Première Vision is an exclusive event for the major luxury and creative brands looking for preview collections from selected Première Vision Paris Exhibitors. For us it is a great opportunity to show off our new paddings collection.

PV: Can you tell us about an innovation or material you’ll be showing at the next Blossom show that you find particularly interesting?

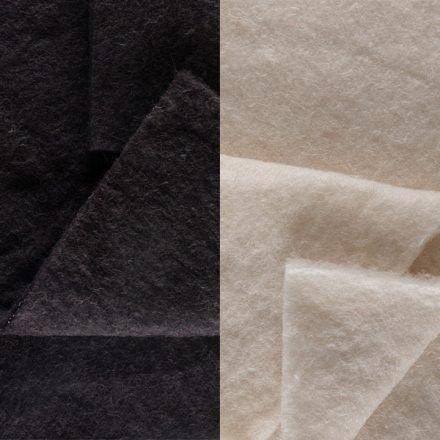

SC: We are very proud of our Nouvelle, the upcycled silk padding from leftover printed silk fabrics, a new frontier in mindful fashion and sportswear. Nouvelle adopts an upcycling approach wherein leftover printed silk fabrics are repurposed to create a new insulating material.

Nouvelle is created in four steps: firstly, we collect as “end of waste” silk fabric scraps from leftover printed silk fabrics, the scraps are garnetted mechanically and transformed into very fine fibers, then we make a decolor (or color) process with GOTS approved substances. Finally, the fibers are blended with PLA (polylactic fiber).

Visit Imbotex Srl on the Première Vision Marketplace ➔