Leather: A Matter of Circularity and Resource Upcycling The - Leather - Première Vision New York - Première Vision Paris - Denim Première Vision

As a by-product upcycled from the agri-food industry, leather is intrinsically aligned with a circular economy approach. All leather-related innovations aim to reinforce this circularity, which can encompass several aspects. The first involves anticipating and managing the end-of-life of the material, with potentially biodegradable developments. The second involves implementing recycling and upcycling processes for production offcuts.

Which Tanning Methods Offer Enhanced Biodegradability?

Leather is rendered rot-proof by tanning. New tanning methods, notably new metal-free synthetic tanning processes using polymers derived from biomass, can promote accelerated biodegradability of leathers.

From an eco-design perspective it is recommended to be sure of a material’s accelerated biodegradability characteristics, and not mislead the consumer by suggesting that the finished product is biodegradable. Thanks to the AGEC law, references such as “biodegradable”, and other similar messages are forbidden on products and their packaging in France. In addition, ISO 20136 certifications confirm biodegradability.

A leather is considered biodegradable when it can break down under the action of living organisms, without causing harm to the environment, according to specific standardized criteria: the time required and degree of biodegradability of the product, non-toxicity, and absence of heavy metals.

There are three factors of attention:

- The natural setting – soil, sea water, fresh water, level of oxygen, pH, temperature, humidity and micro-organisms activating the process.

- The structure and the properties of the leather – raw material, construction and various treatments it has received.

- The degree of decomposition and the time needed for disintegration – to be described as biodegradable, the standards require a product to disintegrate by at least 90% in 6 months.

In general, this Autumn-Winter 25-26 season, tanners are paying special attention to the entire lifecycle of the material, developing new solutions to upcycle their leather scraps.

Options for upcycling finished or semi-finished leather offcuts also include creating new materials. Recycled or regenerated leathers have been on the market for a long time, but their look and composition have significantly evolved. Today, petrochemical-based binders and finishes are gradually being replaced by plant-based or bio-sourced alternatives.

A Focus on Some of the Latest Innovations

Gruppo Mastrotto (IT)

Gruppo Mastrottois specialized in bovine leathers for the footwear, leather goods, upholstery and automobile sectors.

The tannery has developed an innovative range of leathers certified biodegradable with no impact on the environment. These are cowhide leathers, metal-free tanned and formulated with biopolymers. The products comply with the ISO 20136 biodegradability standard.

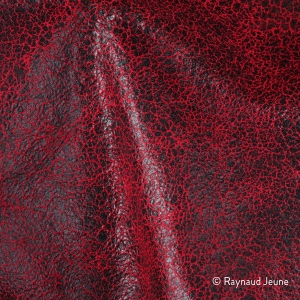

Raynaud Jeune (FR)

Ictyos (FR)

Ictyos is France’s newest tannery. Based in the Lyon region since 2018, the company works exclusively with marine hides (salmon, sturgeon, trout). Ictyos recycles fish-scale residue and other bio-waste as compost and fertilizer.