Smart Tech Expert: Digitalising Design, With Style3D The - Première Vision Paris

To accompany the latest white paper from Première Vision and The Interline—“Fashion & Technology: Why Smart Tech Is Transforming Fashion”—we talked with four different technology companies to obtain their perspectives on how technology is reshaping the way we work in key areas, from design to supply chain transparency.

In this exclusive interview, we talk to Eric Liu, Founder and CEO of Style3D, who will be exhibiting at the Autumn / Winter 2024-25 edition of PV Paris. We discover how 3D workflows are helping to bring ideas to life more quickly, reduce the environmental footprint of a style, replace traditional photography, revolutionise production, and unlock new possibilities in creative expression.

One of the biggest contributors to negative outcomes in fashion is the time it takes to turn an idea into a reality. This affects everything from the profitability of a product to its environmental footprint. How can working in 3D transform those timescales and influence those outcomes?

The nature of fashion is an industry that requires physical deliverables based on predictive layers. It carries an inherent uncertainty. The continuous cycle of new product releases and the emergence of novel creative ideas stimulate consumers. Traditionally, during extensive research and development phases, we relied heavily on patterns, prototypes, fabric, and dyeing. While these methods adapt to the nature of fashion, they pose contradictions with sustainability.

With the evolution of the metaverse, fashion will primarily exist in a “show” format. Digital garments facilitate online presentations by consumers, without the need to physically manufacture clothes, aligning perfectly with the future trend of the fashion industry.

For example, our virtual fashion show projects with different brands enabled a preview of new collections in a 3D environment, creating a buzz without producing a single physical garment. And on average, the entire process from mood boarding to actual sampling has been shortened to just 7-10 days, representing a significant reduction in traditional timelines. In addition, the adoption of our technology has led to a more than 40% increase in efficiency in the communication flow between teams.

A key factor in fashion’s environmental impact is the waste and resources used in the creation of multiple rounds of physical prototypes and samples for every finished product. How can 3D sampling and a digital bill of materials help overcome this?

3D enables the creation of digital samples. It enhances precision in fashion R&D—leading to a quicker and more accurate understanding between designers, pattern makers, and sample-makers, boosting R&D efficiency. It also reduces the need for multiple physical prototypes and shortens the R&D cycle, aiding in stock management. 3D samples come with high-similarity, editability, manufacturability, and detailed garment data(in a form of digital BOM). They can directly connect to the production end, supporting pre-sale of new releases.

Read also: Smart Tech Expert: Transforming Transparency & Sustainability, With Fairly Made®️

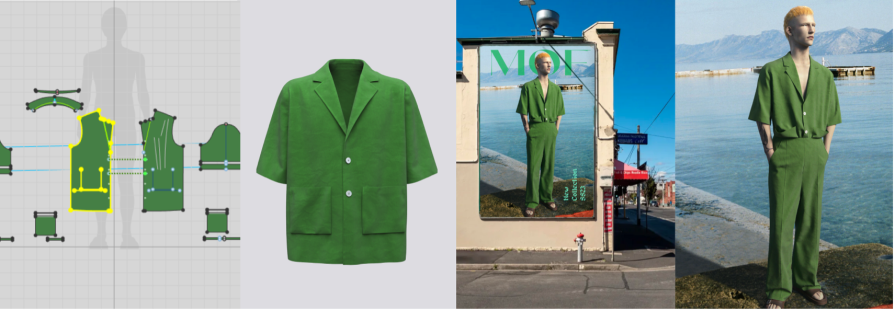

Today, most product photography for apparel is still managed by creating a physical product, dressing a human model, and conducting a photoshoot. This can be a very slow process, and one that’s expensive to scale. What does the alternative look like – using 3D assets, digital models, and virtual showrooms to sell to wholesale partners and retail consumers?

3D assets and virtual showrooms offer rapid mass production of images from various angles and details, without the need for physical models or studios. This drastically reduces photography costs. Unconstrained by time and space, the digital realm allows the maximal expression of design ideas. Digital models and virtual showrooms can be used repeatedly, edited multiple times, reducing marketing costs and unnecessary wastage from physical setup. Virtual showrooms can also host interactive online sessions with users, enhancing immersion and consumer engagement. We also envision the reconstruction of “people, goods, and field”.

Future fashion brands can entirely build digital personas and digital goods to diversify traffic sources and build digital fields, genuinely establishing a digitized “people, goods, field” ecosystem.

An embodiment of this groundbreaking initiative is our latest cutting-edge 3D solution, “Styleverse” launched recently, Styleverse epitomizes how brands and manufacturers could be revolutionarily empowered to create and market 3D content intelligently and seamlessly connected. This avant-garde innovation underpins our commitment to advancing the frontiers of the digital fashion industry.

Read also: Smart Tech Expert: Revolutionising Product Journeys, with TrusTrace

Beyond the way a 3D asset looks, it’s also vital for it to be closely anchored into a 2D pattern, so that users can simulate changes in real-time, and so that the 3D render is as close as possible to the final product. How do you approach linking 3D creation to real production within the Style3D suite?

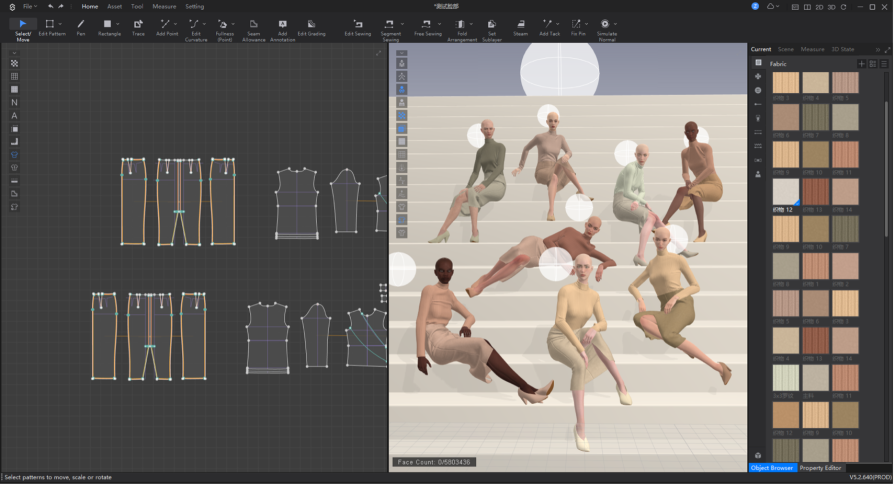

At Style3D, we utilize cutting-edge graphics technology, achieving nearly 50 patents in areas like CAD modeling, simulation rendering, and dynamic simulation. Our prowess in these fields allows us to excel in digitalizing the human body, fabric, and clothing, enhancing 3D display capabilities and ensuring precise simulation and editability.

Emerging directly from the fashion industry, we integrate the unique demands and application scenarios of the sector into our product development.

With extensive structured clothing data at our disposal, we have established a robust link between research and development and the actual production environment. Our comprehensive platform enables seamless collaboration and 3D/2D integration, transforming traditional workflows into efficient digital processes. A pivotal component of this integration has been our recent acquisition of Assyst. With Assyst’s powerful 2D CAD systems, we’re uniquely positioned to provide an all-in-one solution that’s truly 3D-centric, making the transition between 2D pattern design and 3D virtual sampling smoother than ever before.

Leveraging advanced cloud-based systems and collaborative design software, we’re able to facilitate real-time collaboration, regardless of geographical location. This integration with Assyst not only enhances the efficiency of the design process, but also minimizes development time and waste, ultimately driving the digital transformation of the fashion industry.

There is still a lot of interest in digital fashion and the possibilities of the metaverse, but for most creators and brands there’s very little certainty in how to actually approach that potential. What do you believe is the right route from designing digitally to actually creating digital products and experiences?

3D acts as an outlet for designers to express their creativity. Many designers want to express themselves, but realizing their creative ideas in the physical world can be exceedingly expensive and restrictive. 3D provides a new way of carrying out creative ideas, and based on this, brands can explore new opportunities to shape their identity.

Brands and designers need to fully embrace and accept 3D technology, exploring how 3D can integrate with their brand.

The maximization of digitalization value can only be achieved by integrating 3D into their work process and upgrading to 3D from the entire industry chain. Style3D provides a series of digital tool chains to help businesses quickly adapt, enjoy digital convenience and efficiency, and refocus on creativity and design competition.

Companies should not only use digitalization to reduce costs and improve efficiency, but also connect with upstream and downstream industrial chains to join the construction of the digital ecosystem. This enhances the industrial value chain of each enterprise, leading to mutual benefits and win-win situations.

Go on the Style3D Marketplace page →